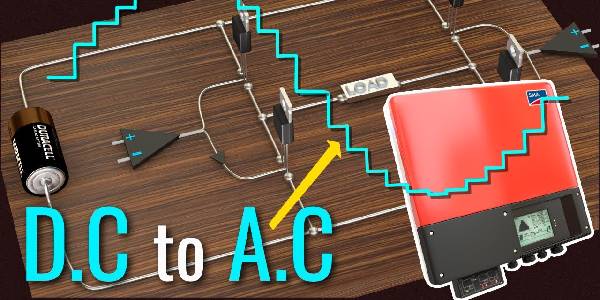

An inverter is one of the useful devices which are used as a power backup for uninterrupted power supply. It is mainly required when there are frequent power outages in your locality. The inverter offers the supply of constant power to the AC voltage when the AC main is not available. There are several popular UPS manufacturers in Chennai. To understand the functioning of an inverter, you must understand its operation under various situations.

Detailed workings of an Inverter is explained below for a better understanding.

AC Power- Available

When there is power available, and thus reaches to the relay and battery charging section of the inverter. The supply would come from the AC mains, and the entire load would be from line voltage. This voltage is also offered to charge the inverter where it is converted into a DC voltage. When the battery or inverter is wholly charged the charging process is stopped.

AC Power-Not Available

When the main current supply is not available, the oscillator circuit present inside the inverter generates and drive signal called MOS drive signal. This signal is amplified in the section where the driver is present, and it reaches the output of the inverter. The switching operation takes place with MOSFETs and transistors, and they are connected as a primary winding of the inverter transformer. When the MOS signal is generated and the switching device turns ON and OFF at the rate of 50HZ. This results in an AC current of 220V at the inverter transformer. This is available in the output socket through a change over relay.

The circuit of an inverter can able to manage various situations like overload, low battery, etc. Thus it can handle the inverter condition standby or running mode. Therefore it is possible to switch the battery to OFF or charging mode. The various working modes can be indicated with the help of the LED lights that are provided in the inverter.

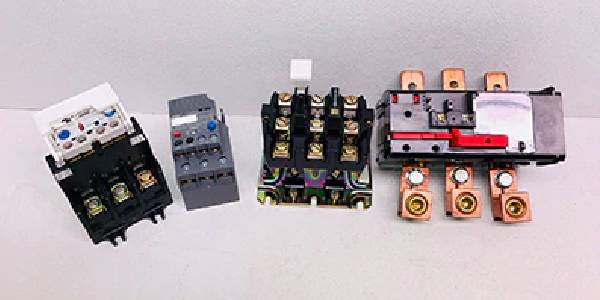

How Does Relay work?

It is basically an electromagnetic switch which is used in the circuit of an inverter. When a single power controls a circuit, then this component is made use of to turn on and off a particular circuit. Various industrial application devices make use of relays for its effective functioning.

It is basically an electromagnetic switch which is used in the circuit of an inverter. When a single power controls a circuit, then this component is made use of to turn on and off a particular circuit. Various industrial application devices make use of relays for its effective functioning.

The basic principle behind the working of a relay is electromagnetic switching. Some of the essential parts of the relay are electromagnet, armature, switch point contact, spring.

The power is offered to the electromagnet with the help of a control switch. When constant current starts flowing, it energizes the electromagnet which creates an intensified magnetic field.

The two basic operations with relays are low voltage and high voltage applications.

The above is the essential operation of an inverter and the functions of a relay in an inverter. The knowledge about the workings of inverter and relays would be of great use.

Read More : Benefits Of Using Reed Switch Technology