What are the primary working methodologies of the overload relay?

The overload relay is an electronic device that turns OFF the motor or the heater automatically when there is an overload. The overload relay turns OFF the engine when a higher voltage is applied; this is more than the suited voltage of the motor pump. The application of the overload relay can prevent the coil inside the motor from getting burnt due to the higher voltage.

Many people are in a big misconception that it is normal for the motor pump coil to get burnt with time. Each rewind of the overload relay can cost up to 7000 – 10000 INR, and hence it is difficult to change the coil of the overload relay regularly.

The burning of the coil can easily be prevented by applying an overload relay, which can turn-OFF the motor when it senses a massive electrical voltage input than usual.

The advantages of using the overload relay

- The overload relay can ensure that the motor is safe and runs for longer life and can also protect the engine from any potential damage.

- The overload relay can also prevent the loss, which can occur due to the breakdown of the water pump.

- The overload relay can protect the motor from being damaged, and hence all the people can save on their yearly budget by minimizing the cost of maintenance and repairs which they spend every year on the motor.

- As the overload relay protects the motor from variant flaws, it is evident that it increases the life-span of the engine.

What are the major types of overload relay?

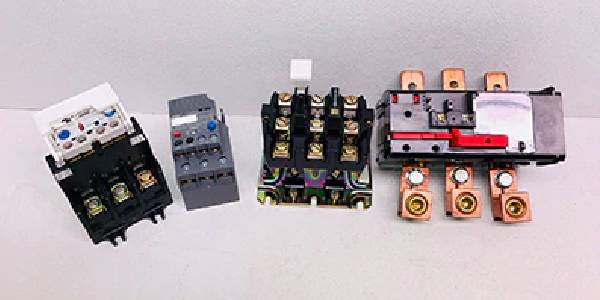

There are two types of overload relay

- Thermal overload relay and

- Digital overload relay

The thermal overload relay trip off the motor when a higher temperature is observed, which is higher than the average temperature.

The digital overload relay monitors the input voltage and current through a digital meter and hence trip off the motor when the voltage value exceeds the average value.

The thermal overload relays were a popular choice of vendors for a more extended period. The only problem with the thermal overload relay is they are climate dependent. On the other digital overload relay does not provide any room to the factors, and hence they can be considered as a good option for modern motors.