Thermal overload relays are useful electrical devices which are used to protect the functioning of motors. It mainly prevents the damage of motor due to overload. Thus thermal overload relays are constructed based on the principle that it would cut power to the motor when too much of current flows for a particular period. Thus thermal overload relays are mostly closed relay. In a motor circuit when there is an increase in temperature, due to excessive current flow, then the relay opens based on the relay type.

Thermal overload relays are similar to the circuit breakers that you install for overload. The main difference between overload relays and circuit breakers is that circuit breakers would interrupt the circuit at the very instant when the overload occurs. But a relay waits for a considerable period and then interrupts the circuit if the overload continues. Thus relays permit overload for an extended period.

Things To Know about Thermal Overload Relays

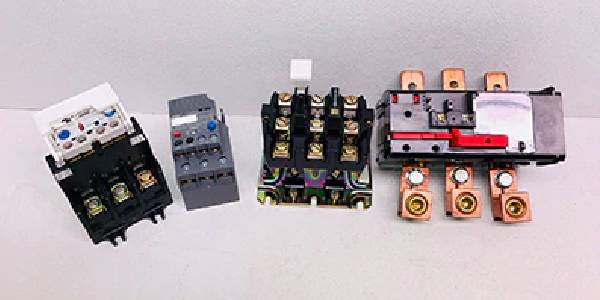

Overload Relay Types

There are three different types of overload relays. They are detailed below.

Bimetallic Thermal Relays: This type of relays make use of a bimetallic strip which opens mechanically. This includes two types of metallic strips with different expand rates when exposed to heat. Thus the metallic strip bends when the temperature increases. A spring is attached to the metallic strip. The spring gets pulled when the excess heat makes the metallic strip to bend. Thus the contacts are pulled, and the circuit is broken. When the bimetallic strip gets cooled, then it gets its original shape.

Solid State Relays: This is an electronic device which does not contain any moving mechanical parts. The relay operates by calculating the average temperature of the motor. This is done by tracking the starting and running currents. It is better to make use of solid state relays as it is faster other than other types of relays. It also features adjustable set points and trip times. Thus they are used in explosive environments.

Temperature Control Relays: The temperature of the motor is sensed by a thermistor or resistance thermal device. These are embedded in the motor winding — the resistance of the device increases as the temperature increases. The threshold circuit detects the increase, and this opens the relay contacts.

Electrical Rating

The following are some of the electrical relay specifications.

Tripping: This is the general term used when the circuit interrupts due to overload.

Full load current range: This is the current range to be set with the relay

Temperature trip Range: This term applies to the relays which measure current instead of temperature.

Trips Class: This is the minimum time that a relay can withstand overload.

Features

Some of the essential features of thermal overload relays are listed below.

- The automatic reset is the feature of the overload relay that returns to the original position after some specified time.

- Ambient temperature compensation is a feature that works efficiently for ambient temperatures.

- Phase monitoring is done to avoid motor damage.

The above are some of the things to know about thermal overload relays.

Read More : A Detailed Overview Of Thermal Relay

Leave a Reply