Relays of the electrical contacts close and open for the operation of other devices. The reason for their usage is because they are cost-efficient when compared to their proportional electronic switches. There are also few relays that are superior in quality to devices that are solid-stat. For instance, relay circuits in output and input are isolated electrically unlike solid-state devices. Relays have many contacts electronically which is isolated from one another. Also, electromechanical relays are now smaller available in surface-mount packages and PCB-mount packages that are best suited for automatic soldering.

There are many advantages of electromechanical relays out of which one is, it has low contact resistance in correspondence to solid-state switches. The contact capacitance is much lower which in turn benefits circuits of high-frequency.

Electromechanical Relays varies in three prime ways

The first type of electromechanical relays that differ from solid-state switches is the relay coils that are known for their high inductivity. The inductance value is also not persistent. After energization, the inductance is quite low and gradually increases as the current approaches and closes the relay armature.

Secondly, the switching time of the relays is much longer. The reasons stated are the coil inductance, armature mass, and contact structures.

Third, it is known to produce high-voltage transients after it is reenergized. The transients can be reduced to an acceptable level by protective circuits but will delay the relay drop.

Reed Relay is limited in quantity by the coil size

It comprises of reed switches in an operating coil. It can be of any configuration type but is limited in quantity because of its coil size. The manufacturers limit the size of the coil to handle maximum switches of 12 standards. Additional contacts can be obtained but the relays must be connected parallel.

Mercury-wetted contact relays consist of glass switches

It comprises glass switches of one or more, while the coil encircles it. The original resistance is maintained within 1 m all around their life.

Contractors

For repeated interrupting and establishing circuits of electric power, contractors are used. The contractors are defined by magnetic and electronic.

Electromagnetic contractors are achieved by means of electromechanical. They break and make the power circuits to load as light, electric furnaces, capacitors, transformers, heaters, etc.

The magnetic contractor comprises of the movable armature and a stationary core. The contractors are designed horizontally, while some have pivoted or hinged clapper magnets. They are available in 600 V, 110 V, 240 V, 380V, 220 V, 480 V, 440 V, and 500 V.

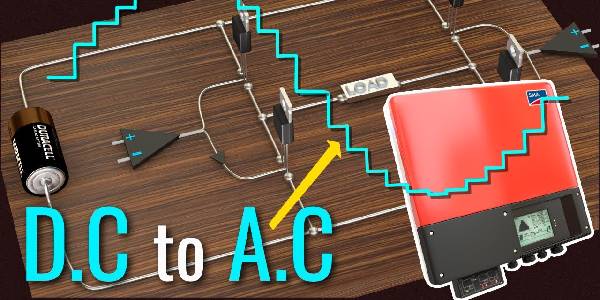

It is basically an electromagnetic switch which is used in the circuit of an inverter. When a single power controls a circuit, then this component is made use of to turn on and off a particular circuit. Various industrial application devices make use of relays for its effective functioning.

It is basically an electromagnetic switch which is used in the circuit of an inverter. When a single power controls a circuit, then this component is made use of to turn on and off a particular circuit. Various industrial application devices make use of relays for its effective functioning.