History of the reed switching technologies in the electrical industry

The year 1936 accounts for the invention of the reed switching technology by one of the renowned team of scientists at Bell Telephone laboratories. Since the design of the reed switching technology, it has increased from large parts to small parts, which are ultra-reliable and durable for working with low power consuming electrical gadgets. The only things which have changed are the production methods and improvised quality optimization in the development of the reed switching technology. The production costs of reed switching technology have also reduced significantly. Let us overview on some of the significant differences between reed switching technology and other switching technologies.

All about the electromechanical relays Vs. the reed switching technologies

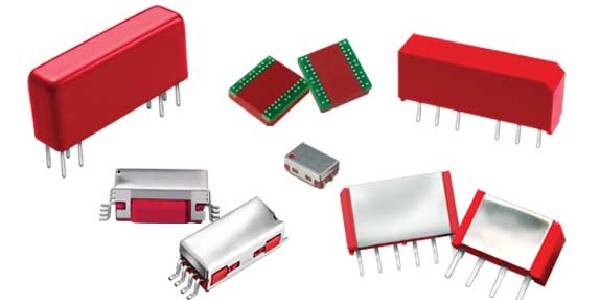

The EMR or the electromechanical relays are widely used in all the major manufacturing industries as they are too cheap and reliable for the switching functions. All the electronic production companies spend a lot on their investment to fetch the EMR or the electromechanical relay for switching purposes. We have mentioned below one some of the key differences between the electromechanical relays and the reed switching technologies

The key differences between the electromechanical relay and reed switching technology

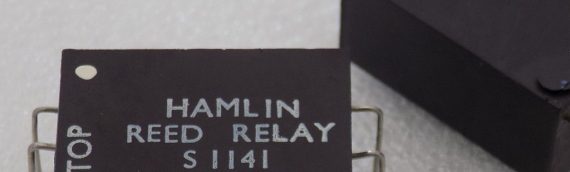

- The reed switching technologies work faster than the EMR as the moving parts in the reed switching technology are much simpler than the electromechanical relay.

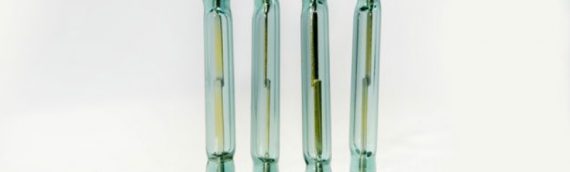

- The reed relays have sealed contacts, and hence they work more efficiently with the low power signals when compared to the EMR as the EMR’s have plastic packages which overtime get damaged due to pollutants and other emissions.

- The reed relays also have longer mechanical life when compared to that of the EMR’s. The main difference in the automated life arises due to the moving parts in both EMR and the reed switching technology.

- The reed switching technology also consumes less power than the EMR switching technology.

- The EMR is designed in such a way that they close in a wiping structure, and hence they clean themselves. But with overtime, the contact plating starts degrading.

- The EMR also offers low contact resistance when compared to the reed switching technology as they possess more extensive contacts, and hence they are only suitable for low resistance.

- The EMR’s also have a higher average rating than reed switching technology as they have more extensive contacts.